Foldaway folding crate

A revolutionary folding crate that meets all the demands of the professional market.

The brief

Didak Injection, an expert in plastic injection moulding, tasked us with developing a folding crate. Not just any folding crate, but the crate that would score highest across all key requirements of the professional market:

- Transport as many goods as possible per crate

- Minimise storage space for folded crates

- Be robust and cost-efficient

As always, we stayed true to our motto: start at the beginning. Read on to discover how we turned this challenge into a strong end result.

Foldaway folding crate

Benchmarking as a catalyst for innovation

Starting from the above challenge, we kicked off with a benchmark, taking a close look at competing crates. We then translated the three key requirements into four concrete parameters:

- A stacking height of 30 mm (space-saving: the lowest stacking height on the market)

- A maximum height of 232 mm without overlap

- A weight below 1.8 kg (the lightest crate on the market!)

- A load capacity of 20 kg

The fact that the Foldaway is now in production confirms that the folding crate meets all three requirements of the professional market and fulfils the four parameters we defined.

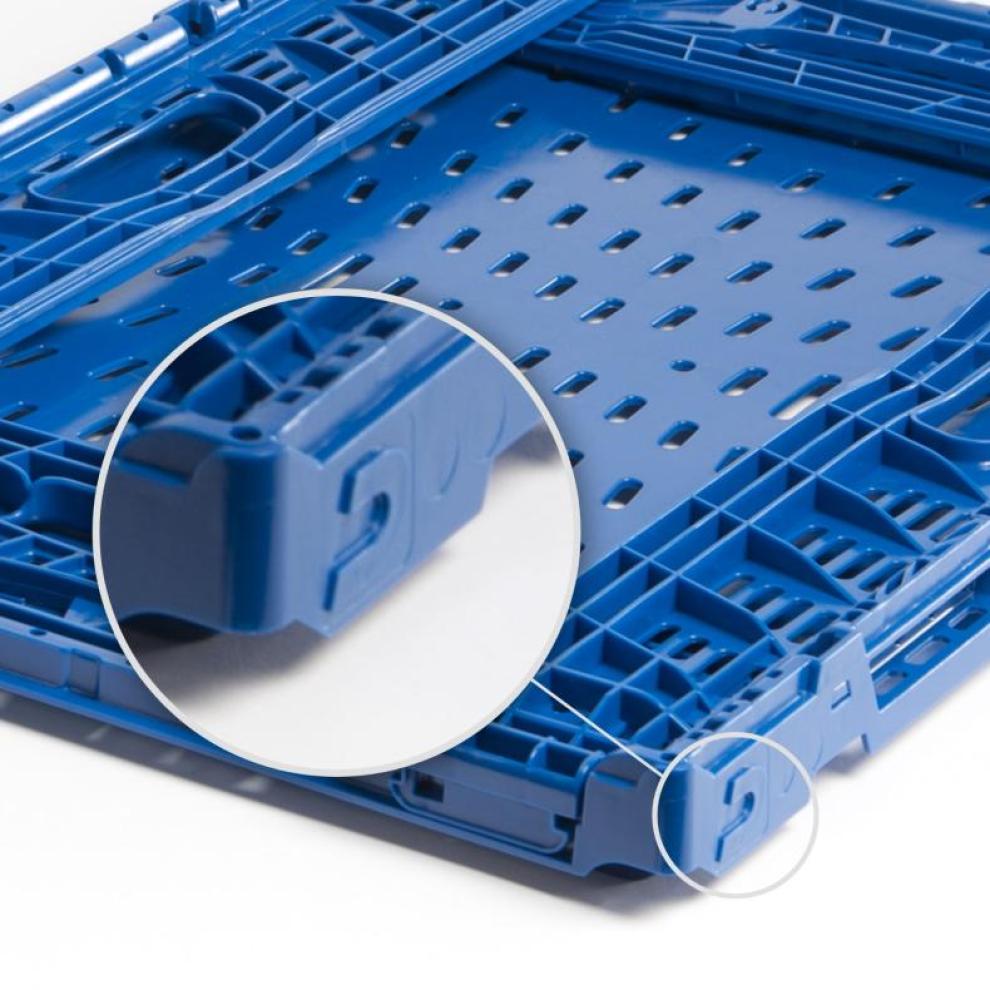

Design in service of branding and strength

At Artori, we don’t believe that a technical product excludes good design. It was important to us to integrate Didak’s visual language into the crates and express the brand as clearly as possible — both when the crate is open and when it is folded.

We therefore worked with a number of subtle design elements that enhance Didak’s recognisability while also contributing to the crate’s structural strength.

Strength calculations for the best possible result

How do we ensure that a folding crate which folds up to 20% more compactly and offers the best volume-to-weight ratio can still carry 20 kg? By applying strength calculations, we developed a folding crate that meets the required standards for strength and safety.

We closely examined wall thickness, reinforcement structures, the effects of deflection, and the material used to manufacture the crate.

From theory to practice through prototyping

Thanks to rapid prototyping, we brought the concept to life by quickly turning ideas into physical forms and testing their functionality.

Using 3D printing at ½ scale, we were able to test the different models (600 × 400 mm and 300 × 400 mm). Full-scale cast parts made with silicone moulds then allowed us to verify whether the design met all requirements of the final folding crates, such as stackability and interlocking.

The result?

The Foldaway is a folding crate that both Didak and we at Artori are extremely proud of. It meets all three requirements of the professional market — where most other folding crates only satisfy one or two. In short, it:

- Folds more compactly than other crates on the market

- Offers the best volume-to-weight ratio

- Expresses Didak’s visual language

- Is produced using 100% green energy, made from a single material and therefore 100% recyclable

Discover the full story of this case in the Foldaway article series.

Do you have an idea you’d like to turn into a tangible product?

At Artori, we don’t shy away from any challenge. Get in touch and discover how we make the difference.