Sustainable flower container

Artori and Didak Injection join forces for a sustainable flower container

Sustainable flower container

Didak Injection, a specialist in injection moulding, was asked to optimise an existing flower container. Flower containers are used to distribute cut flowers between wholesalers, ensuring they arrive in our homes in perfect condition. Back in the 1980s, a plastic version of such a container already existed, but over time cardboard boxes became the standard — resulting in a significant amount of waste.

The goal of the assignment was to develop an environmentally friendly alternative to disposable corrugated cardboard flower boxes. Didak entrusted Artori with this challenge based on our previous successful collaborations, including the innovative Foldaway folding crate.

And so we got to work, using the original plastic version from the 1980s as our starting point.

Below, we highlight the key improvements.

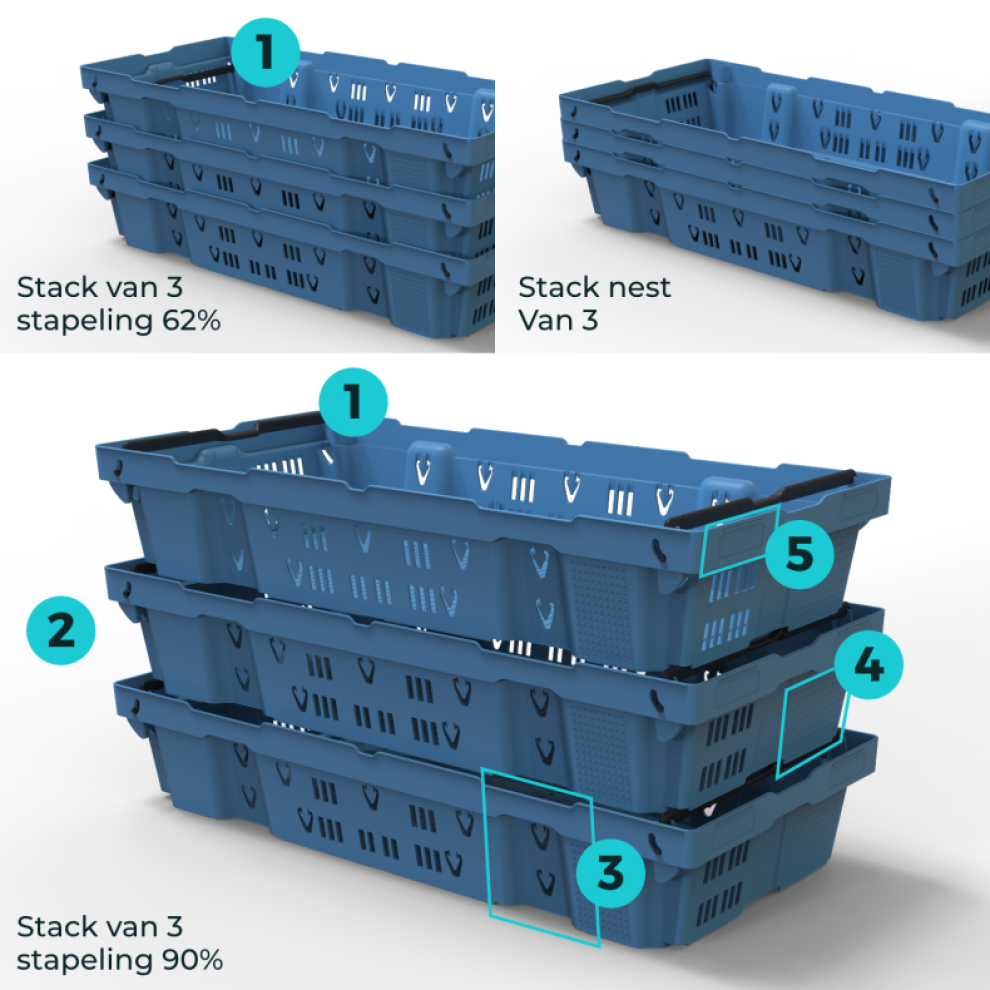

Optimisation with a focus on logistics

- 1. Optimised bale arm: more efficient transport for partially filled containers

-

The previous version of the flower container could only be nested or stacked in its fully closed state using a metal bale arm. With the new, redesigned bale arm, containers can now also be stacked when filled to 60%, reducing the space required during transport. The new bale arm is made of plastic instead of metal, improving recyclability. Whereas the arm in the old version hung loosely next to the container during nesting, the updated arm is now foldable into the rim to prevent snagging.

- 2. More capacity

-

The new flower container is lower in height, allowing more containers to be stacked during transport, while offering a larger capacity of 122 litres compared to 112 litres in the previous version. This was achieved by using a straight rim instead of a U-shaped one, combined with plastic with a foaming agent to provide the required strength.

- 3. Notches for strap fastening

-

Notches were added at both the top and bottom to allow straps to be easily secured around the containers.

- 4. Easy-to-remove stickers

-

The sticker areas feature a textured surface to make removing stickers easier.

- 5. Voorziening voor RFID-tags

-

RFID tags are integrated into the top rim to support automation. RFID — or Radio Frequency Identification — uses radio waves to wirelessly read or transmit information. This technology involves a tag that can be easily attached to the flower container.

- 6. Optimised base with rib pattern for automation

-

The underside of the container features a rim for stable placement on the ground, along with a rib pattern that provides additional grip on conveyor belts — a crucial element for automation.

Optimisations for efficiency and comfort

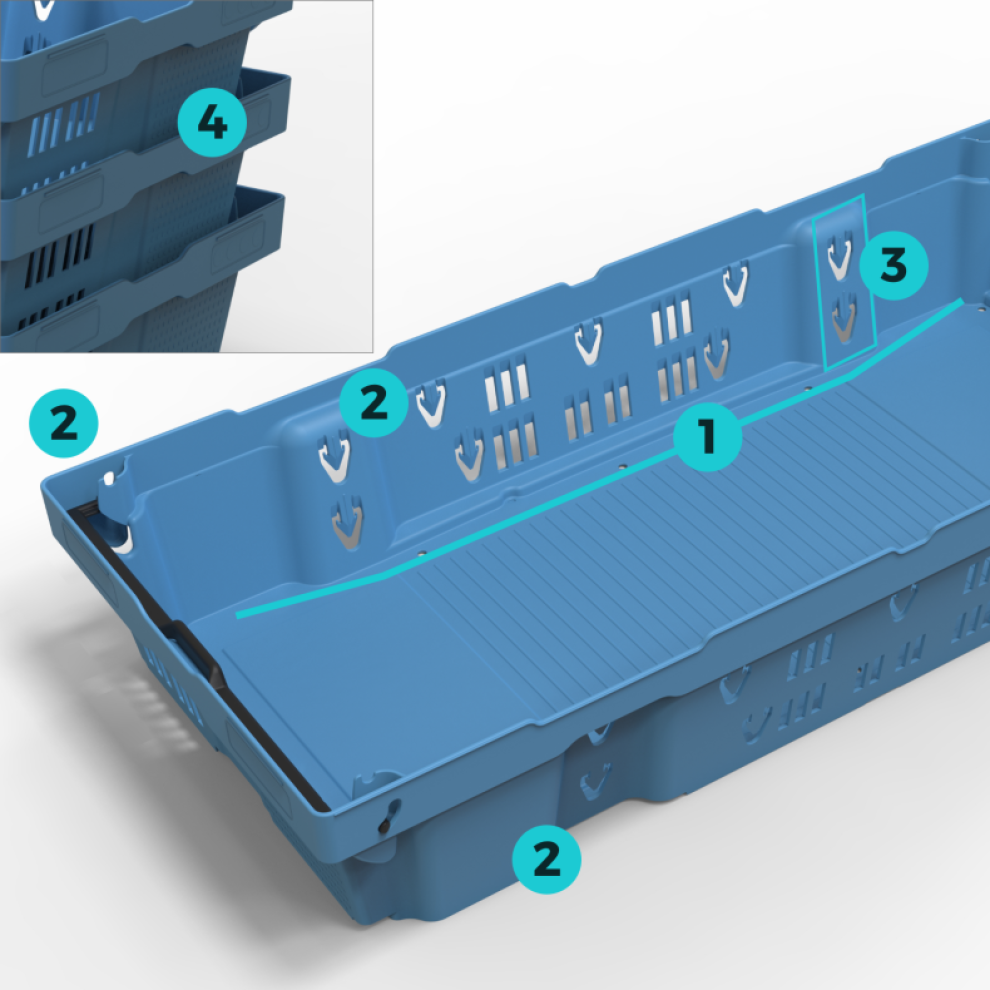

- 1. Optimised base for improved water drainage and protection of flower buds

-

The base was redesigned with a concave shape, allowing water to be efficiently guided towards the drainage holes. In addition, raised surfaces were added for the flower buds to rest on, keeping them dry and preventing contact with water.

- 2. Improved cleanability through rounded edges and drainage holes

-

All edges were rounded to improve cleanability, with the drainage holes further contributing to a more efficient cleaning process.

- 3. Reinforced hooks for secure attachment of cardboard sheets

-

The hooks have been reinforced. Cardboard sheets are placed on top of the flowers and secured to the hooks with elastic bands.

- 4. The muschel grip provides an improved, comfortable and fully integrated handle.

-

A muschel grip is a specially designed handle that offers an ergonomic and space-saving solution, as it has no protruding parts.

In summary: efficiency and sustainability through smart improvements

The redesigned flower container combines logistical efficiency with sustainability. With a recyclable plastic bale arm, increased capacity, RFID integration and improved fastening options, the container optimises transport.

Enhancements such as an optimised base for water drainage, rounded edges for easier cleaning and reinforced hooks improve ease of use and support automation. Together, these innovations make the container more functional, more durable and ready for today’s logistical challenges.

Do you have a product you want to make more sustainable, more efficient or simply smarter?

At Artori, we combine design, engineering and production expertise to turn technical challenges into well-considered solutions. Get in touch and discover what we can do for your product.