Smart engineering

in practice.

At Artori, we believe that products are truly valuable if they are not only cleverly conceived, but also technically feasible and economically viable. Our cases show how we work with customers to translate complex ideas into producible solutions: step by step, substantiated and hassle-free.

From feasibility analysis to production launch, we contribute ideas, we challenge, and we deliver.

Discover what that looks like in practice.

Beologic

Tortu foodcontainer

Technical feasibility analysis

Engineering

Production launch & testing

Renders & animations

Tal

Fabian diffuser

Production

Pollet Water Group

Eva Jane water softener

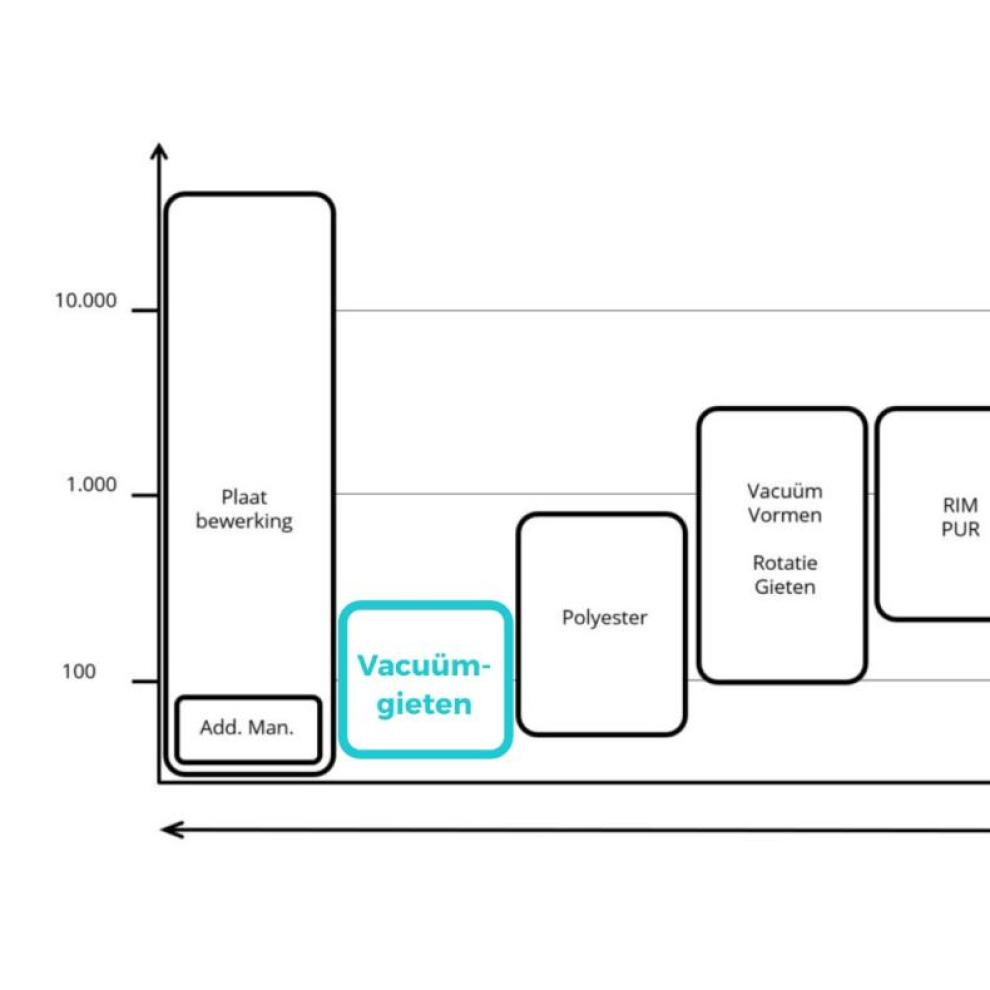

Technical feasibility analysis

Design

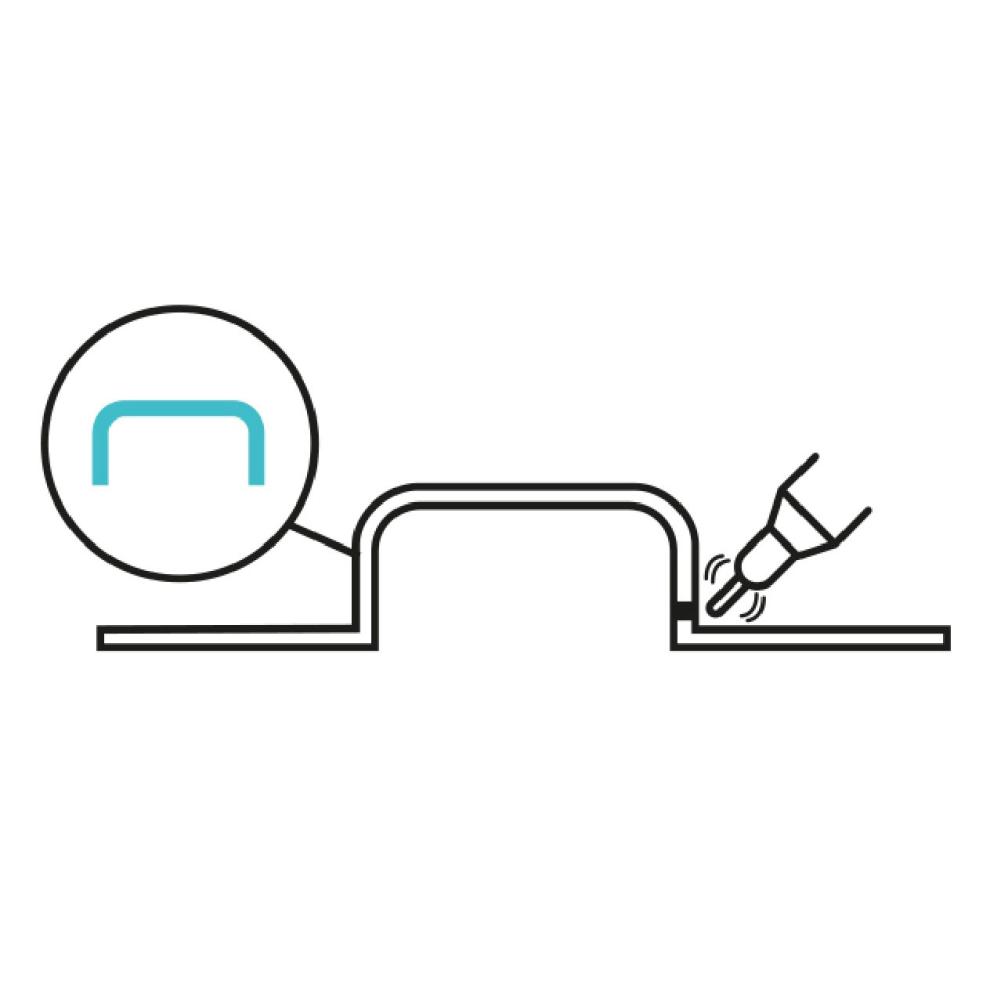

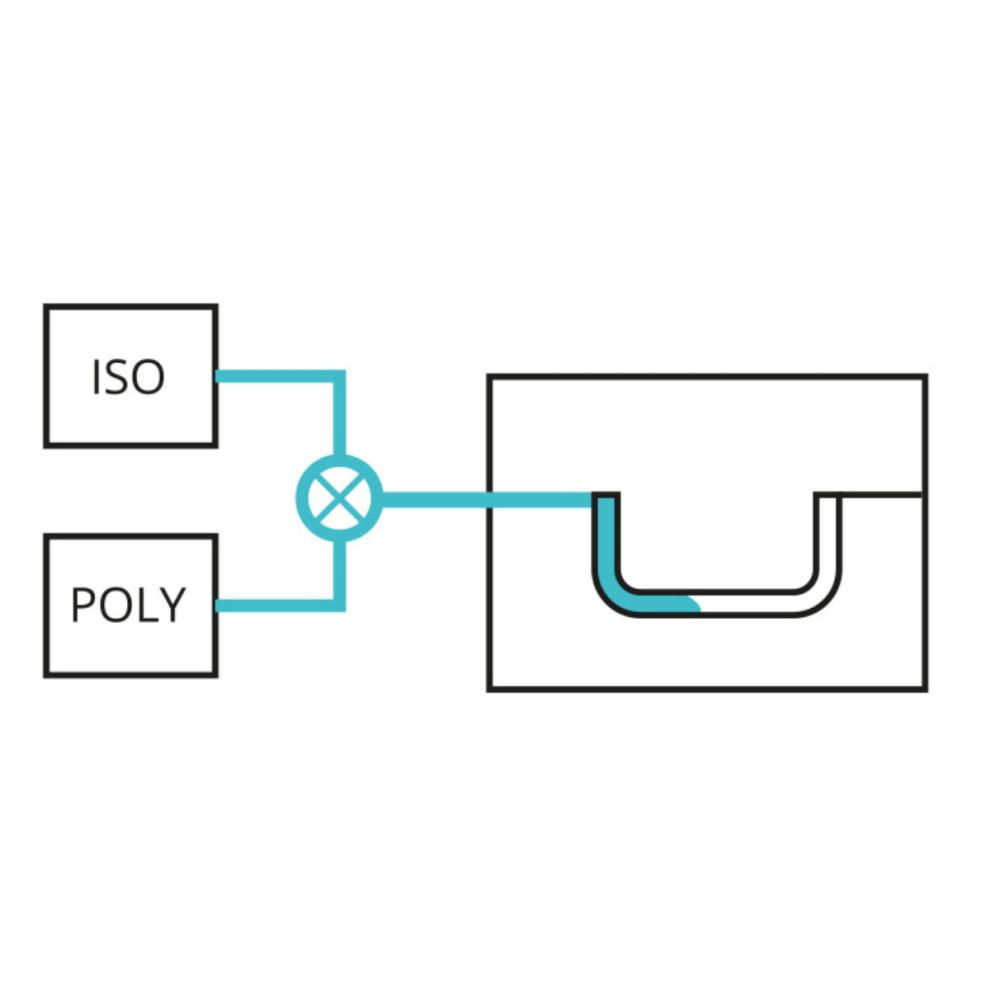

Engineering

Production launch & testing

Renders & animations

Devaplus

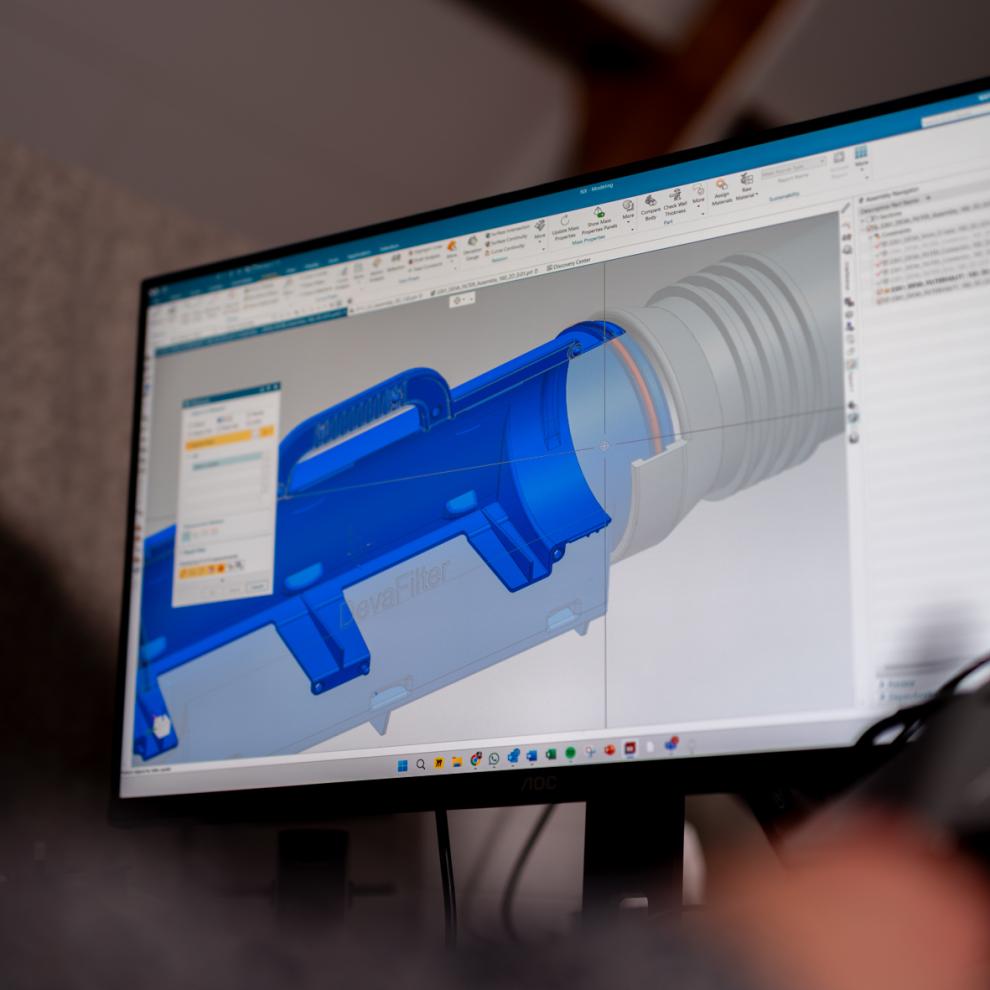

Devafilter

Engineering

Televic Rail

Test Jigs

Engineering

Production