Charger case

When the people from Ticto NV came to us, they already had a first design for the charger, but no partner who could realize this.

The charger was designed to be manufactured from plastic sheet material, the ideal production method for their then annual circulation of +/-50 units.

Charger case

The digital badges and chargers quickly proved a success and shortly after the first production, the start-up was taken over by the international Rightcrowd. The products received a boost and under the Covid measures, the badges were also used for social distancing and contact tracing. As a result, the production need rose very quickly.

Increasing the volumes triggered Artori to rethink the production process. Plastic sheet material was the ideal solution for low volumes, but resulted in too high unit prices and too long production cycles for large volumes.

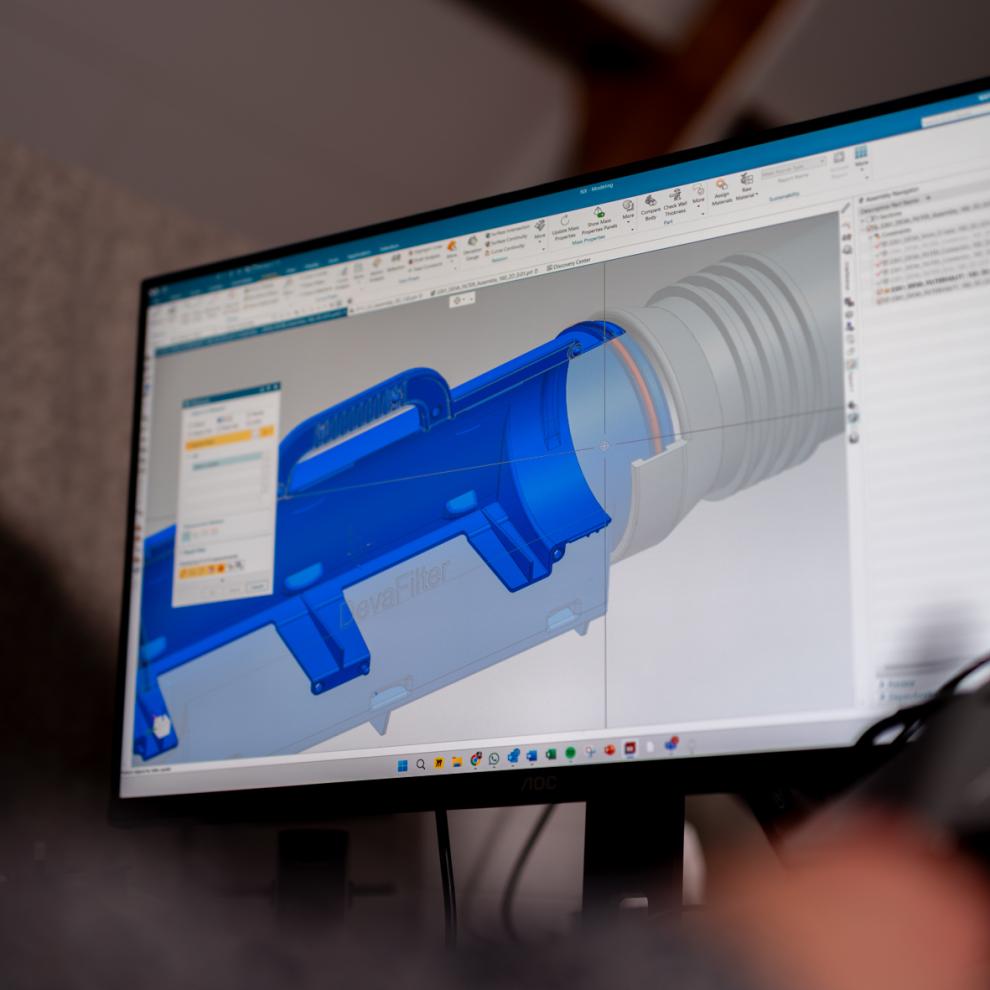

We looked at whether there were other technologies that, taking into account the new numbers and depreciation of a possible mould, resulted in a better unit price and faster delivery times. In addition, the initial design and color scheme were also questioned.

Taking all parameters into account, it turned out to be possible to switch to high-pressure injection moulding. The design was largely kept but we have decided to switch to a design with 1 color. That way both parts could be incorporated in 1 mould, which made production a lot cheaper. Injection moulding reduced the number of parts, simplifying assembly. A win-win situation in all areas!

The process:

- Choice of material and technology (13/11/2020 – 18/11/2020)

a. Choice of economic production process

b. Rudimentary 3D: based on this, a piece + mould quotation was drawn up - Engineering + testing (18/11/2020 – 25/11/2020)

a. Detail engineering

b. 3D printing prototype - Order mould + FOT’s: 27/11/2020

- Delivery FOT’s + color adjustment (04/01/2021 – 07/01/2021)

- Delivery first series: 28/01/2021

It was a challenging process, but due to the efficient approach and short communication lines, this was achieved in a lead time of 2,5 months. The new chargers were put into use in February ’21!