High-pressure injection moulding versus chemical foaming injection moulding

At design bureau Artori, we combine expertise and technological know-how to turn your product into a success. We assess feasibility, production methods and material selection, then move efficiently into the design phase — ensuring no time or budget is wasted.

In addition, we provide full production support and collaborate with specialised partners who apply a range of technologies, including high-pressure injection moulding and chemical foaming injection moulding.

Below, we briefly explain both technologies and outline the situations in which each is best applied.

High-pressure injection moulding versus chemical foaming injection moulding

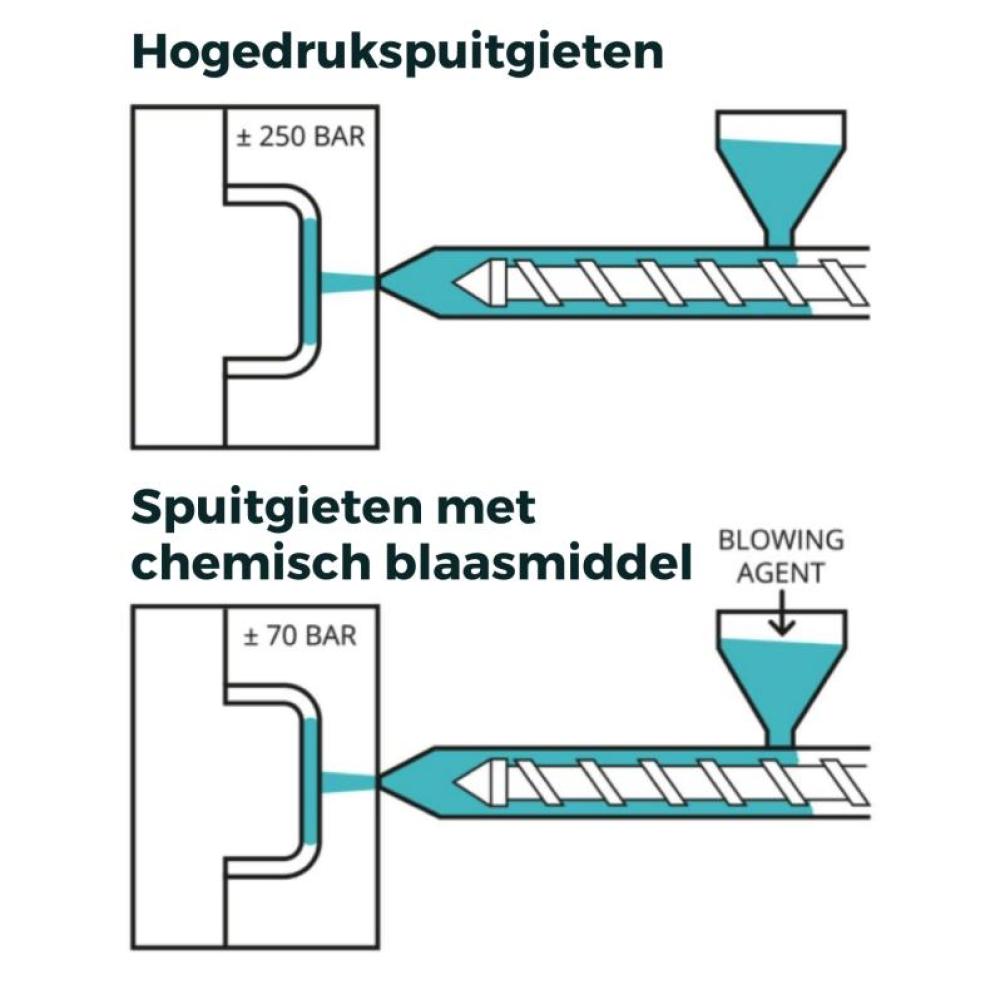

High-pressure injection moulding

In high-pressure injection moulding, plastic (virgin or recycled granulate) is heated in the screw and injected into the mould under high pressure. The mould is completely filled, with sufficient packing pressure applied to prevent sink marks in the final product.

After cooling and solidifying in the mould, the product is ejected.

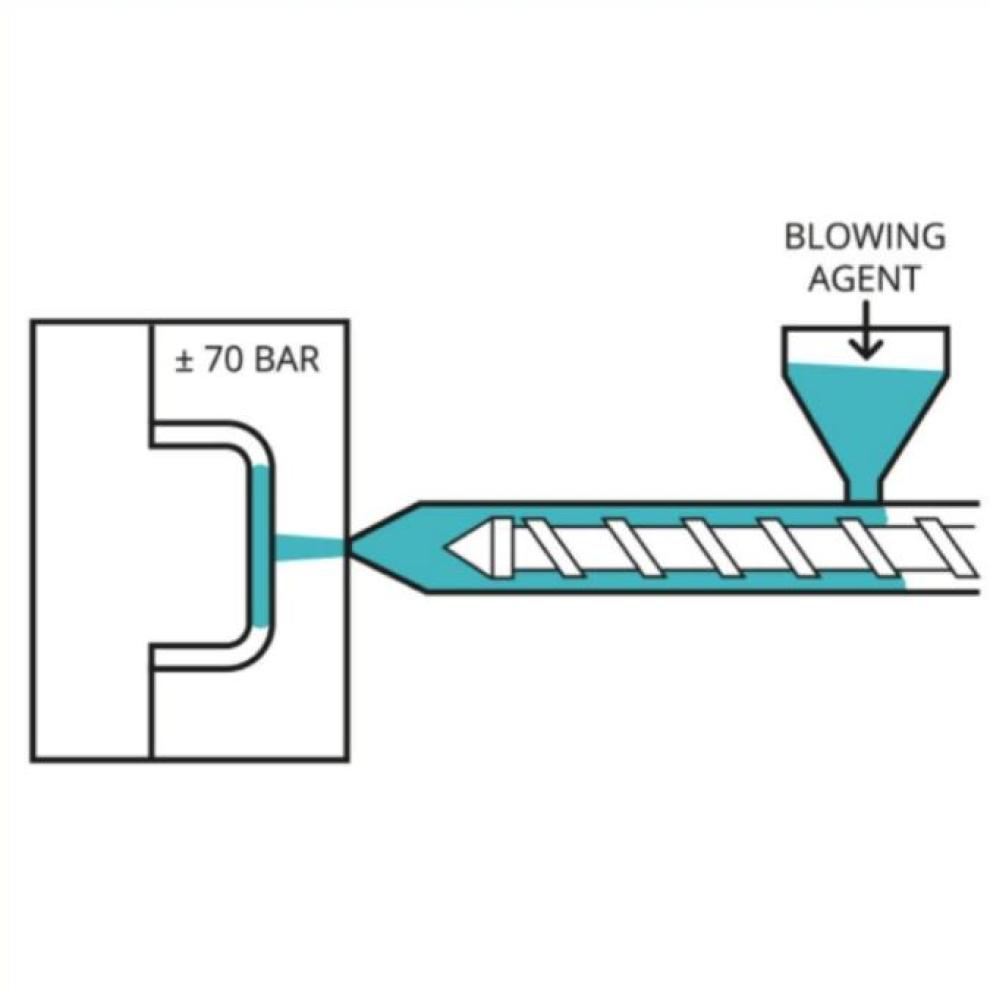

Chemical foaming injection moulding

In chemical foaming injection moulding, plastic is heated in the screw and injected into the mould — just like in traditional high-pressure injection moulding. However, this process takes place at much lower pressure. A chemical blowing agent is added to the plastic, filling the mould to approximately 90–95%.

The blowing agent causes the plastic to foam, creating gas bubbles that expand to completely fill the mould. This results in a foam structure within the plastic. After cooling, the product is ejected from the mould, yielding a lightweight final product.

Weighing high-pressure injection moulding versus chemical foaming injection moulding

The choice between these two technologies is carefully evaluated on a product-by-product basis. Below are several scenarios in which specific criteria can influence the decision:

- Looking to create a product with slightly thicker walls without long cycle times?

Adding a small amount of blowing agent can be highly effective. - Need damping properties?

Chemical foaming injection moulding offers a significant advantage, as the foam structure improves vibration damping and impact resistance. - Searching for insulating properties?

A blowing agent is an excellent option. Depending on density and wall thickness, insulation levels can range from cork-like performance to that of expanded polystyrene. - Working in a sector where weight reduction is crucial?

Using a blowing agent reduces weight, depending on the density and thickness of the part. - Aiming for a premium aesthetic with high surface quality?

High-pressure injection moulding is the preferred choice. Chemical foaming injection moulding can create a clouding effect on the surface, often requiring an additional coating layer when appearance is a priority. - Is straightness critical and warpage unacceptable?

Adding a blowing agent can help. Because the mould can be fully filled without high packing pressure, internal stresses are reduced, resulting in straighter parts with less warpage.

Curious to see a real-life example of a product made using high-pressure injection moulding?

Follow us on social media — we’ll be sharing an interesting case very soon.

Want to discover which technology best suits your product?

Get in touch with us for no-obligation advice and find out how we can help turn your product into a success.