Rotation moulding

Rotation moulding is a technique for the manufacturing of hollow products in small to middle-sized series. For rotation moulding we use cast aluminium moulds or moulds made out of sheet steel.

Rotation moulding

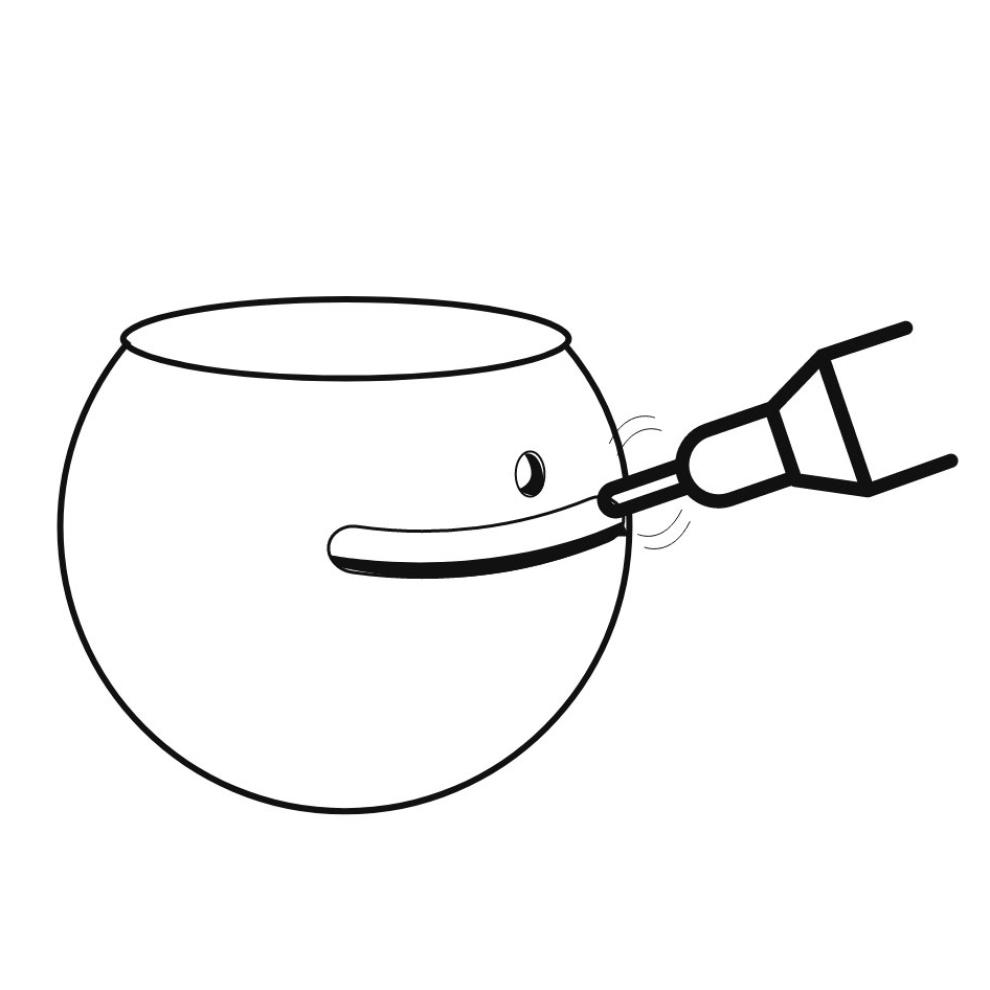

Step 1:

We fill the mold with plastic powder and close it.

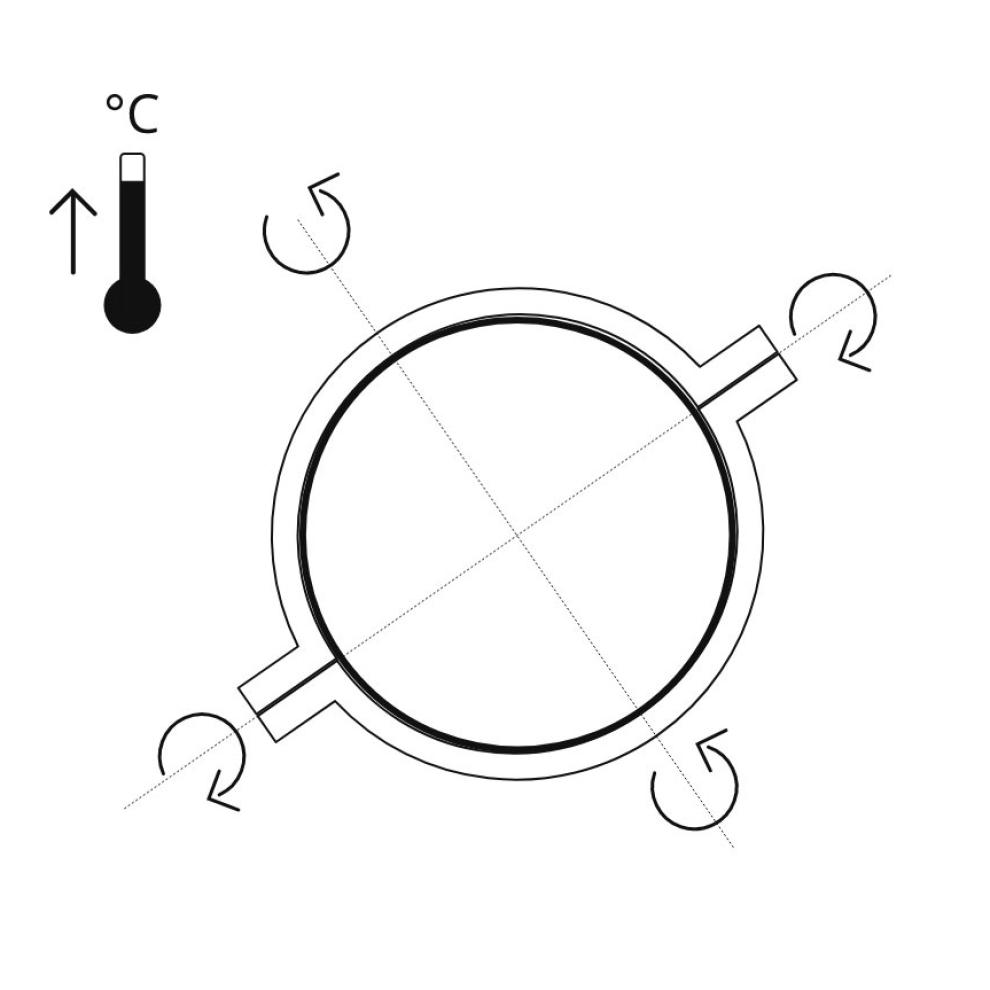

Step 2:

We rotate the mould on both its vertical and horizontal axes and heat it in an oven or with open flames, causing the plastic to melt and distribute evenly across the inside of the mould.

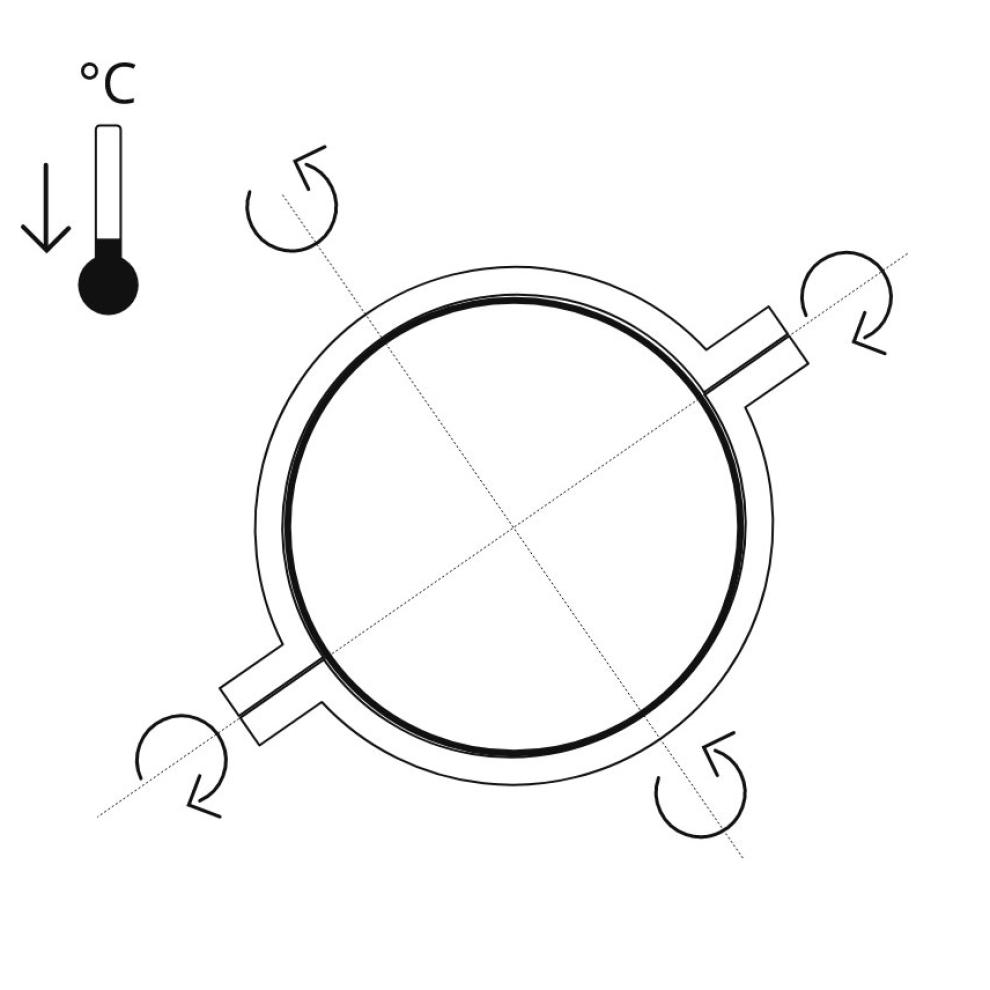

Step 3:

We remove the mould from the oven or take away the flames, and it continues to rotate while cooling in the open air.

Step 4:

After cooling, we open the mold and remove the product.

Stap 5:

Indien gewenst, voorzien we het product van gaten of openingen door middel van CNC frezen.