All news

Reaction injection moulding

Reaction Injection Moulding (RIM/PUR) is the ideal technique for small to medium-sized series of complex products with a slightly greater wall thickness. The large variation in PUR-compositions allows for the production of soft to hard products.

Reaction injection moulding

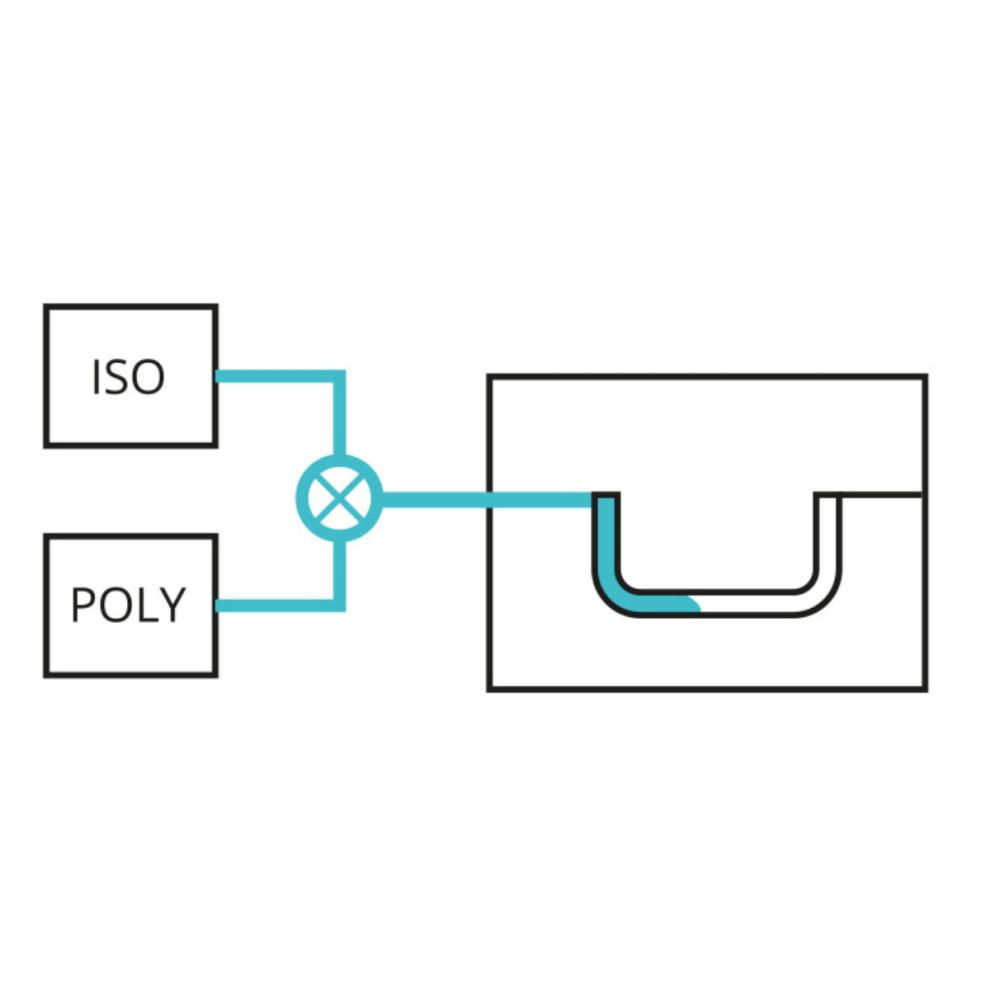

Step 1:

Depending on the desired hardness the PUR-components (polyol and isocyanate) are injected in different quantities into the mould through a pump.

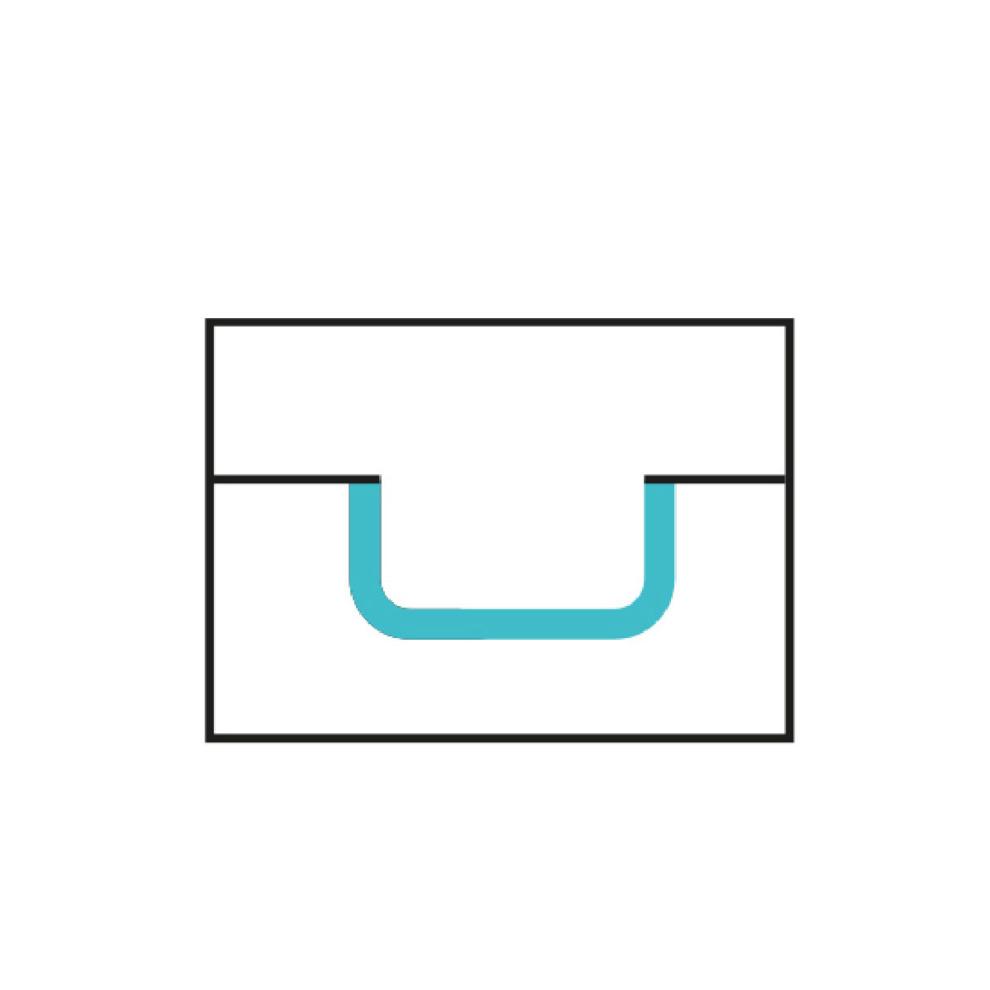

Step 2:

The mould is filled for 60 to 80 % with this mixture. Because of the chemical reaction the product froths and fills the mould completely.

Step 3:

After curing, we remove the product from the mould and finish it (deburring, lacquering,…).