Low pressure injection moulding

Low pressure injection moulding or structural foam injection (SFI) is the ideal technique for medium-sized series. In comparison with the classical high pressure injection moulding, this involves products with a slightly greater wall thickness. Aluminium moulds are used.

Low pressure injection moulding

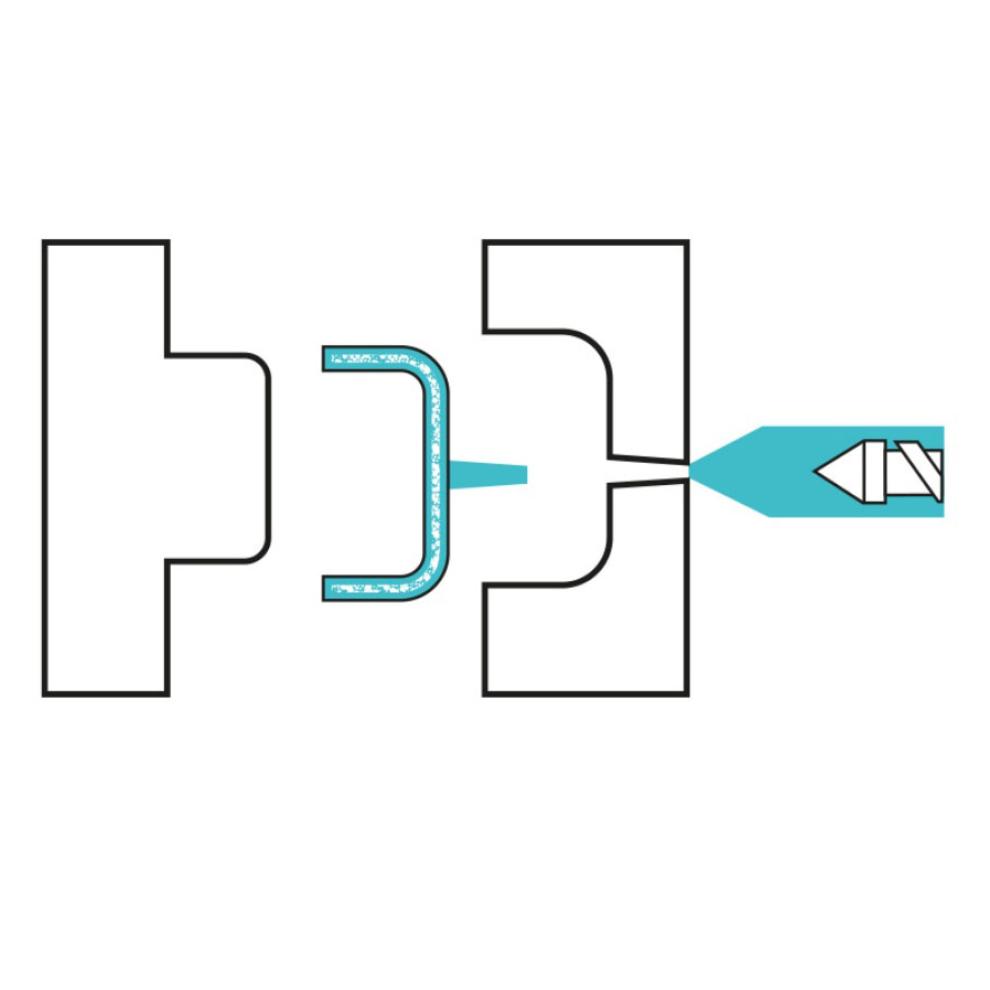

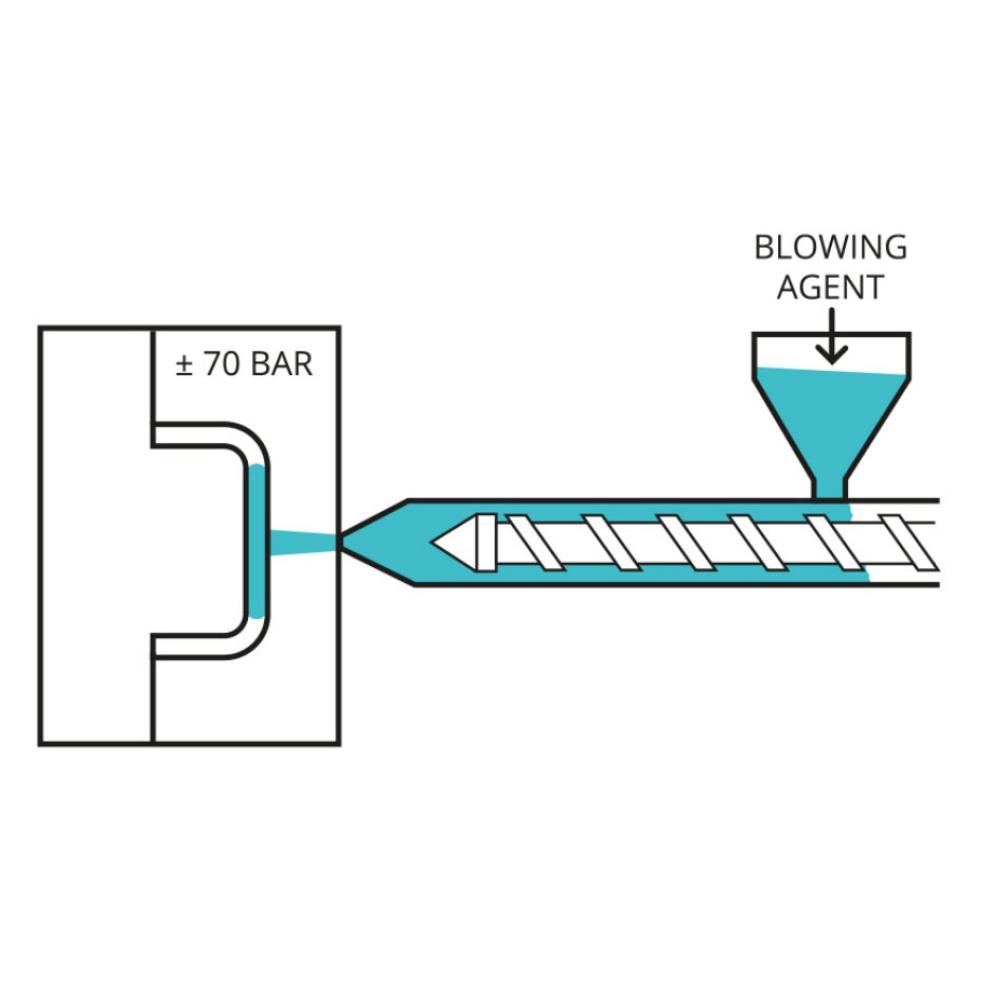

Step 1:

As with the classical high pressure injection moulding, the plastic is heated in the screw and injected into the mould. With SFI this happens under a much lower pressure, however. Apart from the plastic, a blowing agent is injected as well.

Step 2:

The mould is filled for 90 to 95% with this plastic. The blowing agent ensures the frothing of the plastic so that the mould gets filled completely.

Step 3:

When it has cooled down, the mould opens and the product is removed.