All news

High pressure injection moulding

High pressure injection moulding is the ideal technique for large series of thin-walled products. Steel moulds are used.

High pressure injection moulding

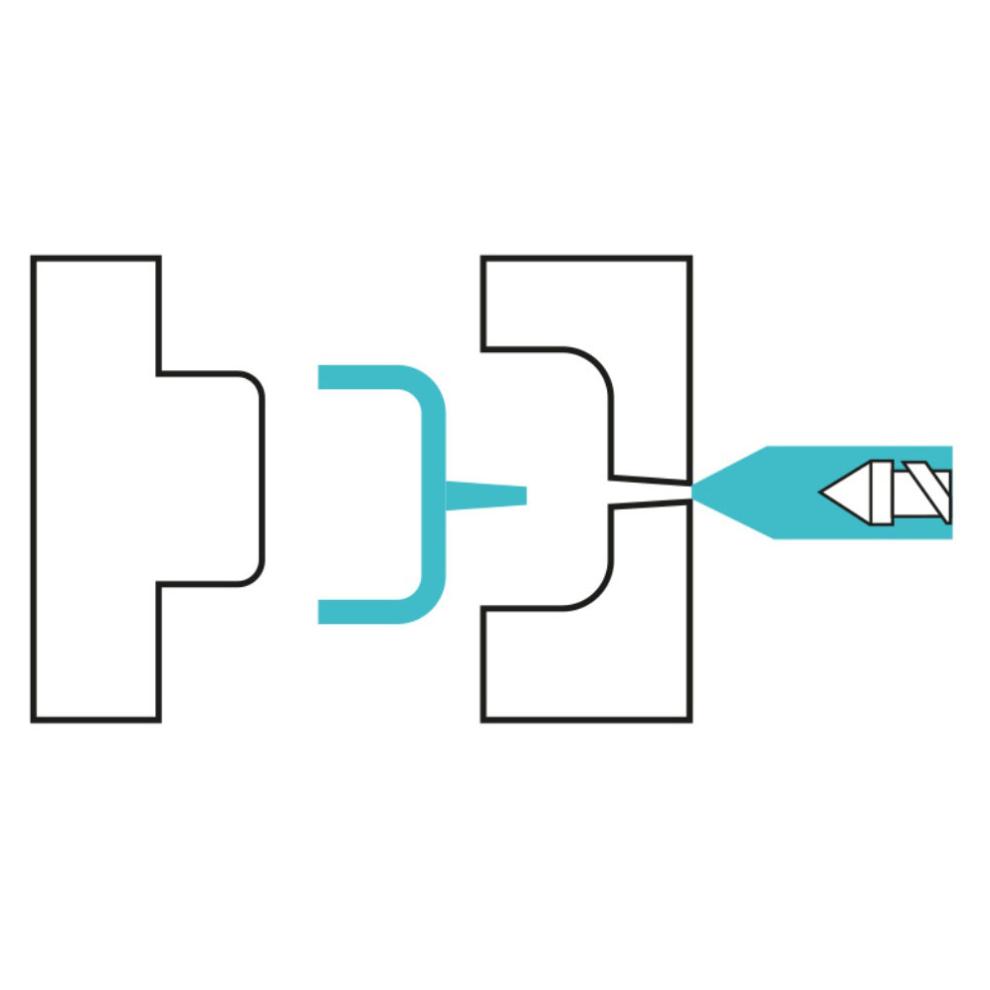

Step 1:

The plastic is heated in the screw and injected into the mould under high pressure.

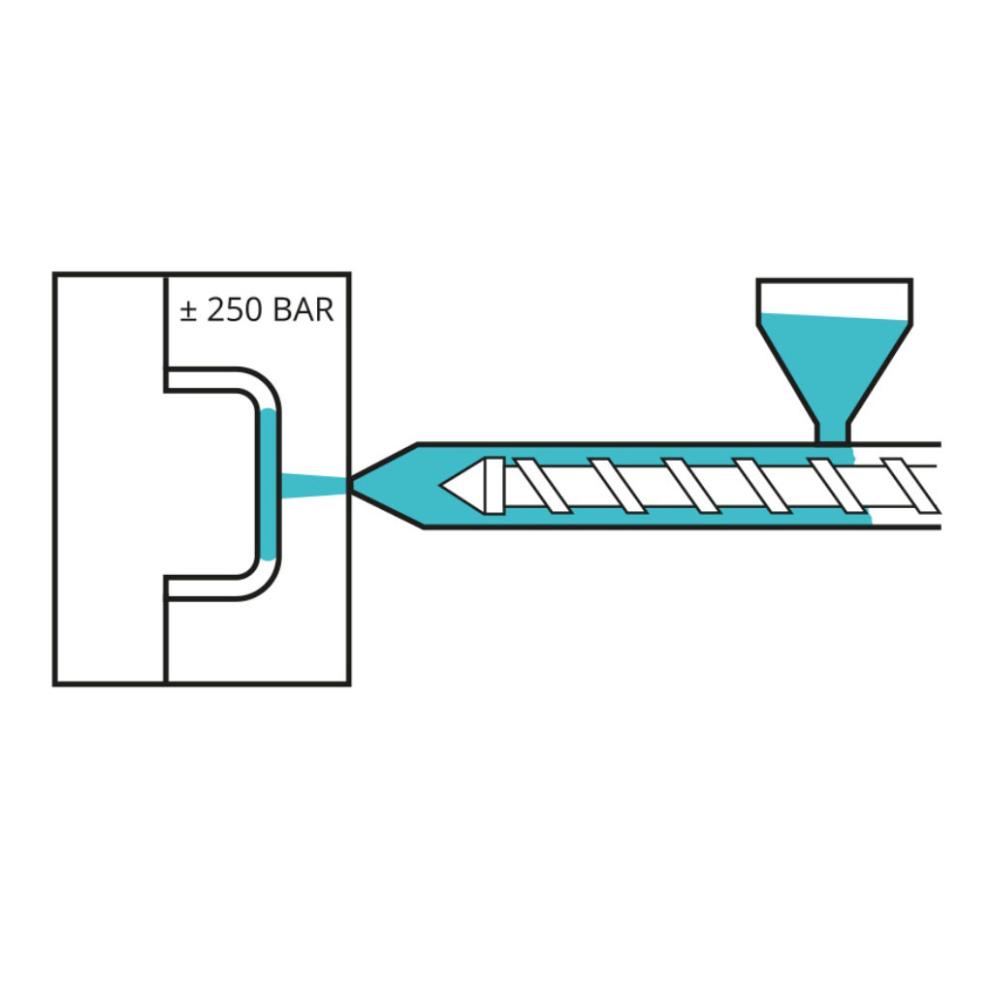

Step 2:

The mould is filled completely and pressure is added to prevent the product from falling in.

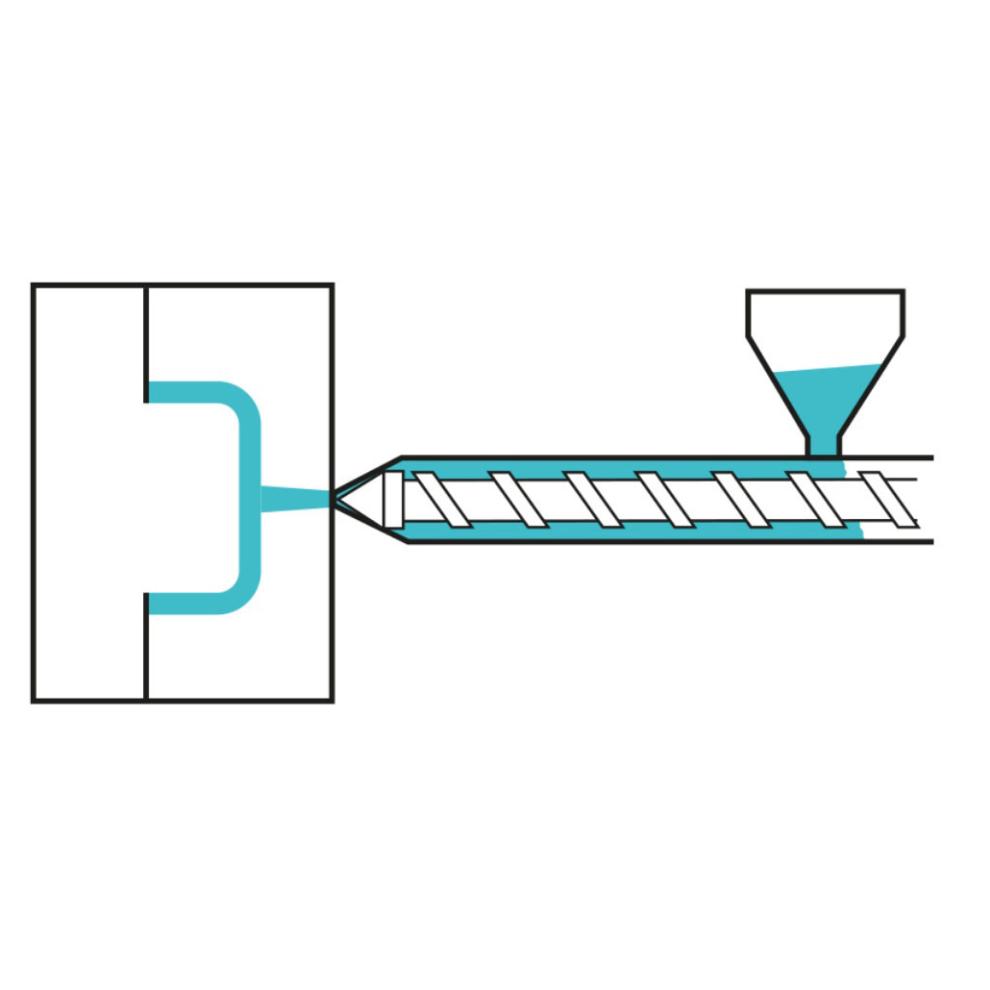

Step 3:

When it has cooled down, the mould opens and the product is removed.